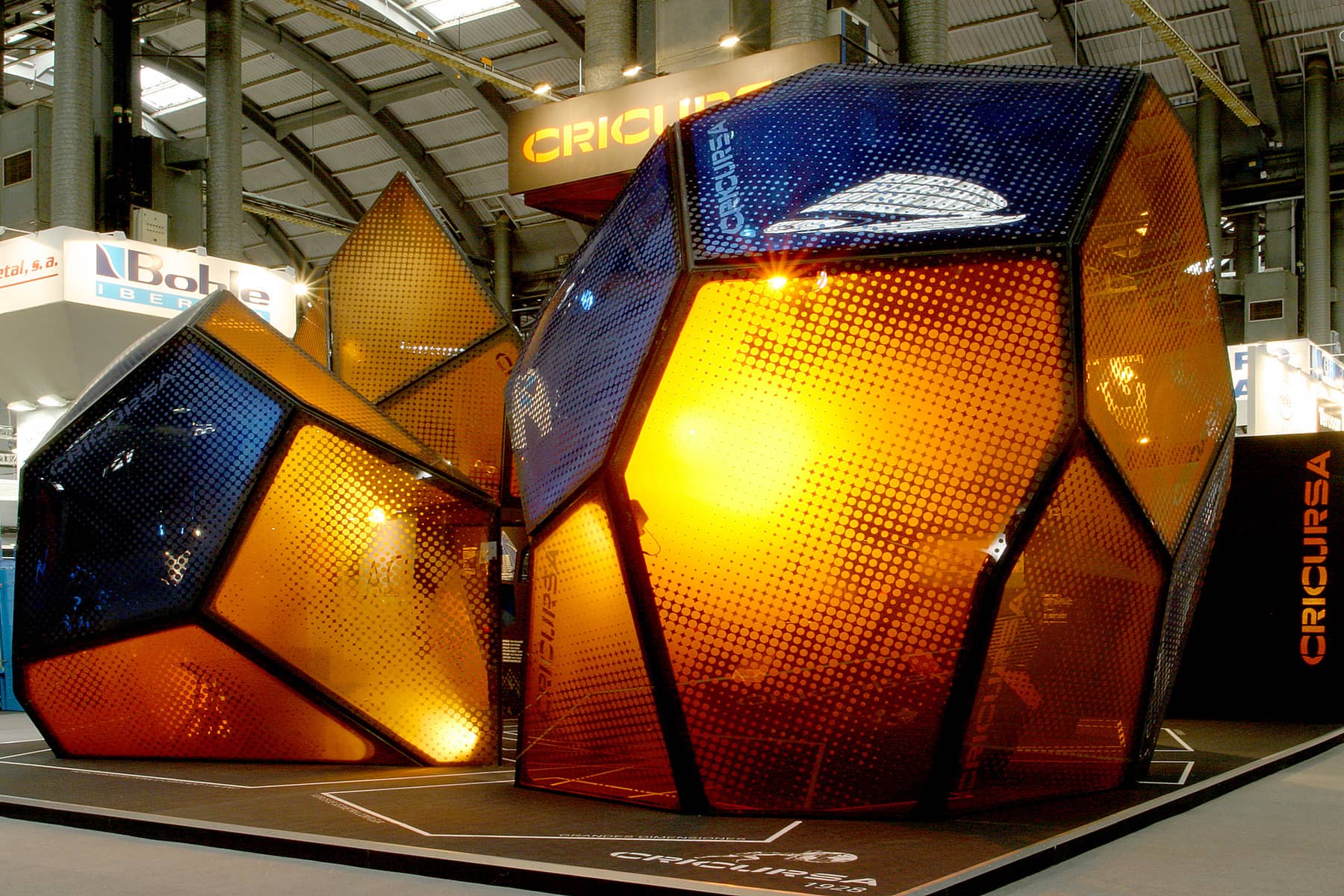

Year

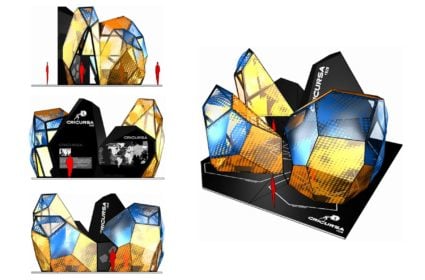

2007SUPERFICIE

100 m²

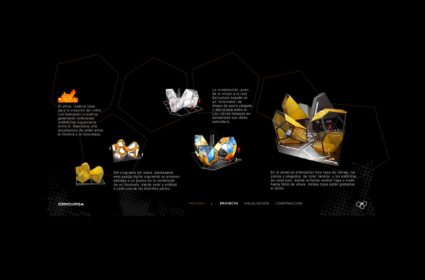

Partner in Charge

Jordi FernándezEduardo Gutiérrez

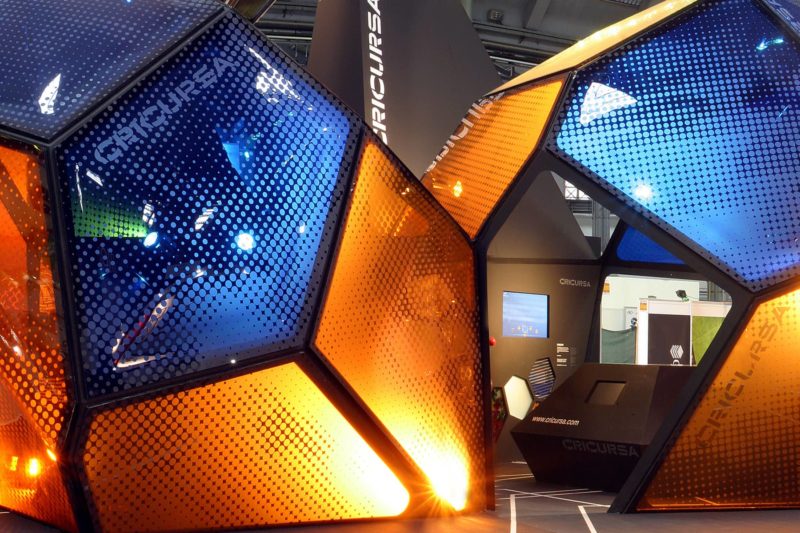

Project Team

Jordi FarellCarlos García-Sancho

Fani Natou

Joan S. Sorrondegui

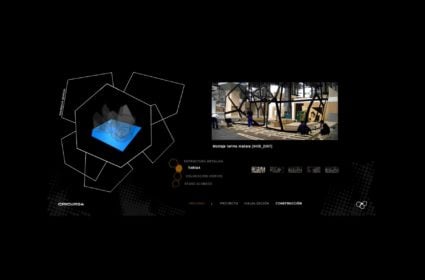

Graphic Designer

Bernardo MagalhaesMULTIMEDIA

Natalia Cambello

Fabian Taranto

(GROTESK DESIGN)